WAVE CHASER BOARDWORX

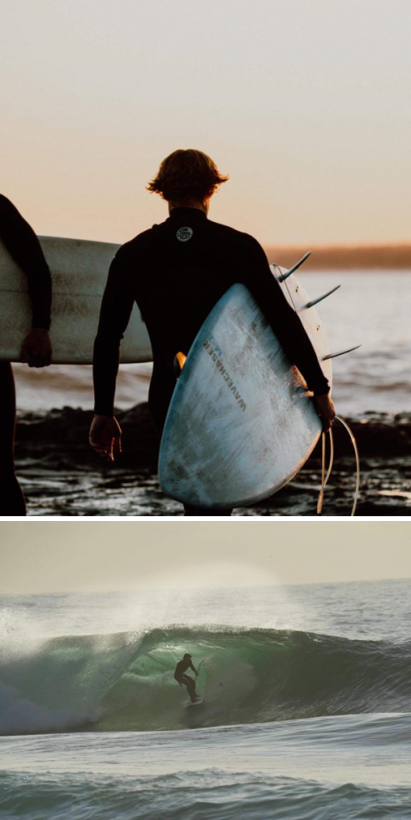

Surf, SUP & Foil Boards Designed & Built in Australia

In 2023, Wave Chaser partnered with local surfboard manufacturers in an initiative to support increasing demand for locally produced custom, and stock sized, SUPs and Foil boards in Australia.

Aside from a few factories venturing into EPS / Epoxy manufacturing, to date, our industry has been focused on traditional Polyurethane / Polyester surfboard manufacturing and has not been equipped to manage the size, shape, materials and construction methodology required to manufacture SUPs and Foil boards.

We’re also looking into the broader economic sustainability issues, seeking material and product supply arrangements with local businesses and personnel support through government, tertiary and industry career pathway incentives.

Wave Chaser will continue to work with an increasingly supportive local surfboard manufacturing industry, with a view to develop high quality, high performance, Surf, SUP and Foil boards, delivered to our customers at more affordable price points than our international competitors.

Wave Chaser equipment is geared to enhance the user experience & our team is driven by an oath; Go Faster, Go Further!

SUSTAINABLE SURFBOARD MANUFACTURING

Sustainable Surfboard Manufacturing is a production methodology that effectively addresses critical environmental and economic issues associated with the development of surfboards.

Wave Chaser is adopting more sustainable production initiatives, from power use, efficient material handling; shaping, layup, fusion, and finishing techniques and processes, whilst using more environmentally friendly materials to develop high quality, high performance, Surf, SUP & Foil boards.

Wave Chaser boards are made with 100% recyclable Expanded Poly Styrene (EPS), a lighter and more buoyant foam than traditional surfboard Polyurethane (PU) foam, and Epoxy resin which has a much higher tensile strength and superior bonding properties than Polyester resin, enabling less material use for a stronger laminate. Compared with PU foam and Polyester resin, EPS and Epoxy require less energy to produce, and less harmful associated chemicals are used in the manufacturing process.

Epoxy resin has about 75% fewer Volatile Organic Compounds (VOCs) than Polyester resin and about two-thirds fewer VOCs are released into the atmosphere when it cures. Epoxy is more resistant to moisture, wearing, cracking, peeling, and corrosion or damage from chemical or environmental degradation and they can be cleaned up with organic citrus-based cleaners rather than flammable and toxic acetone, which translates into a more environmentally friendly product overall.

We can always do more! We’re analysing the use of bio foams and resins, PET (recycled plastics) and more sustainable, eco-friendly, woven materials including flax, hemp, basalt, recycled carbon fibre and reusing waste material from our manufacturing processes.